AI Monitoring

Ai-feature

sorting

Intelligent Line Insight

This is a space to share more about the business: who's behind it, what it does and what this site has to offer. It’s an opportunity to tell the story behind the business or describe a special service or product it offers. You can use this section to share the company history or highlight a particular feature that sets it apart from competitors.

To test and continuously improve our technologies, we operate a dedicated AI monitoring center that analyzes real waste streams from a major metropolis of nearly 6 million people. The data is used to train and refine neural networks, improving detection accuracy and operational efficiency across

all sorting lines.

Ai-feature

sorting

100 times

per second

To test and continuously improve our technologies, we’ve established a dedicated monitoring center that analyzes waste streams from a major metropolis with a population of nearly 6 million people. This large-scale, real-world data allows us to train and refine our neural networks, constantly increasing the accuracy and efficiency of our sorting systems.

Monitoring

How much money

is wasted?

20+

Types of sorted

materials

plastic bottles

oil bottles

milk bottles

detergent bottles

tin cans

tetrapacks

glass bottles

20+

Types of sorted

MSW materials

plastic bottles

oil bottles

milk bottles

detergent bottles

aluminum cans

tetra pak

glass bottles

construction

and demolition waste

The AI monitoring algorithm compares objects against predefined accept and reject criteria to identify and remove defective items or foreign materials from the production line. It also separates products of different grades or material types for recovery and reuse.

wood chips

chipboard

mixed granules

fine granulate

asphalt granulate

concrete granulate

secondary sand

cardboards

24/7 AI Monitoring system

SKU: 0000

The AI monitoring system ensures secure data processing and full operational visibility. Customisable dashboards let operators track performance, adjust parameters, and analyse results in real time. Continuous model updates improve detection accuracy, keeping sorting lines efficient

around the clock.

>95% detection accuracy

Correct AI classifications

0.01 second per frame

High processing speed

Put it by the drop,

see a lot

Why сamera position changes everything

Put it by the drop, see a lot

Why сamera position changes everything

InSystem AI :

Smart Enough for Chaos

Any Waste. Maximum Detection.

No Compromises

Real-world production

We operate in real industrial environments, where waste streams are always complex and messy. This is exactly where our AI proves its strength, reliably and accurately detecting all valuable fractions even in the most unpredictable flow.

Controlled environment

Competitors demonstrate only "laboratory" scenarios with neatly sorted material, but their systems struggle to perform reliably in real world conditions.

significant reduction in camera blind spots

<70%

AI monitoring detects more fractions than competitors

6х

thinner waste stream than on-belt analysis

Put it in the right place

Why сamera position changes everything

When the camera is placed exactly where it should be – above the waste stream – the difference is dramatic.

️InSystem monitoring system

significant reduction in camera blind spots

<70%

AI monitoring detects more fractions than competitors

х6

thinner waste stream than on-belt analysis

other monitoring systems

Our AI monitoring camera is mounted at the end of the belt discharge point. This position lets the system analyze the complete waste stream as it leaves the belt. With a clear view of every item, the setup detects up to 70% more material fractions than competing systems.

When the material drops, its speed increases to around 3 m/s. The stream spreads and thins by roughly a factor of six, which exposes materials that were hidden in the dense flow. The AI monitoring software then detects and classifies these newly exposed material fractions, improving accuracy and recovery.

Automatically updating algorithm

Updated image processing algorithm

Data

on sorting results

24/7

Monitoring system

1. Data from all connected cameras is securely transmitted to a unified control center for continuous remote monitoring and service.

2. Sorting algorithms are automatically optimized improving detection accuracy and adapting to increasing waste volumes across all facilities.

InSystem AI :

Smart Enough for Chaos

Any Waste. Maximum Detection. No Compromises

Real-world production

We operate in real industrial environments, where waste streams are always complex and messy. This is exactly where our AI proves its strength, reliably and accurately detecting all valuable fractions even in the most unpredictable flow.

️InSystem Monitoring System

We operate in real industrial environments, where waste streams are always complex and mess. This is exactly where our AI proves its strength — reliably and accurately detecting all valuable fractions even in the most unpredictable flow.

️InSystem Monitoring System

real-world production

Controlled environment

Competitors demonstrate only "laboratory" scenarios with neatly sorted material, but their systems struggle to perform reliably in real world conditions.

Other Monitoring SystemS

InSystem AI : Smart Enough for Chaos

Any Waste. Maximum Detection. No Compromises

Updated image processing algorithm

Data

on sorting

results

24/7

AI Monitoring system

1. Data from all connected cameras is securely transmitted to a unified control center for continuous remote monitoring and service.

2. Sorting algorithms are automatically optimized improving detection accuracy and adapting to increasing waste volumes across all facilities.

InSystem software

Our AI monitoring software gives full control over production, linking robots with cameras and providing instant access to real-time performance data. Its flexible configuration adapts to any factory setup, ensuring seamless coordination and precise operational oversight across all connected systems.

Compatible products

Seamless monitoring across all

InSystem sorters

insystem.io monitoring system

Test drive

Book a demo

Get a calculation of how our technology

will impact your business metrics

Integrate InSystem products to enhance

your business

Сloud statistics

The cloud platform provides full visibility into your sorting operations across all sites. Real-time analytics, automated reports, and configurable dashboards deliver precise insight into system performance. Designed for easy integration and secure data processing, the platform enables faster decisions and smarter control.

REALTIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

Industries

AI-powered waste sorting solutions for efficient material recovery and zero-waste goals.

Cloud statistics

The cloud platform provides full visibility into your sorting operations across all sites. Real-time analytics, automated reports, and configurable dashboards deliver precise insight into system performance. Designed for easy integration and secure data processing, the platform enables faster decisions and smarter control.

REAL TIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

Industries

Our AI monitoring camera is mounted at the end of the belt discharge point. This position lets the system analyze the complete waste stream as it leaves the belt. With a clear view of every item, the setup detects up to 70% more material fractions than competing systems.

When the material drops, its speed increases to around 3 m/s. The stream spreads and thins by roughly a factor of six, which exposes materials that were hidden in the dense flow. The AI monitoring software then detects and classifies these newly exposed material fractions, improving accuracy and recovery.

InSystem software

Our AI monitoring software gives full control over production, linking robots with cameras and providing instant access to real-time performance data. Its flexible configuration adapts to any factory setup, ensuring seamless coordination and precise operational oversight across all connected systems.

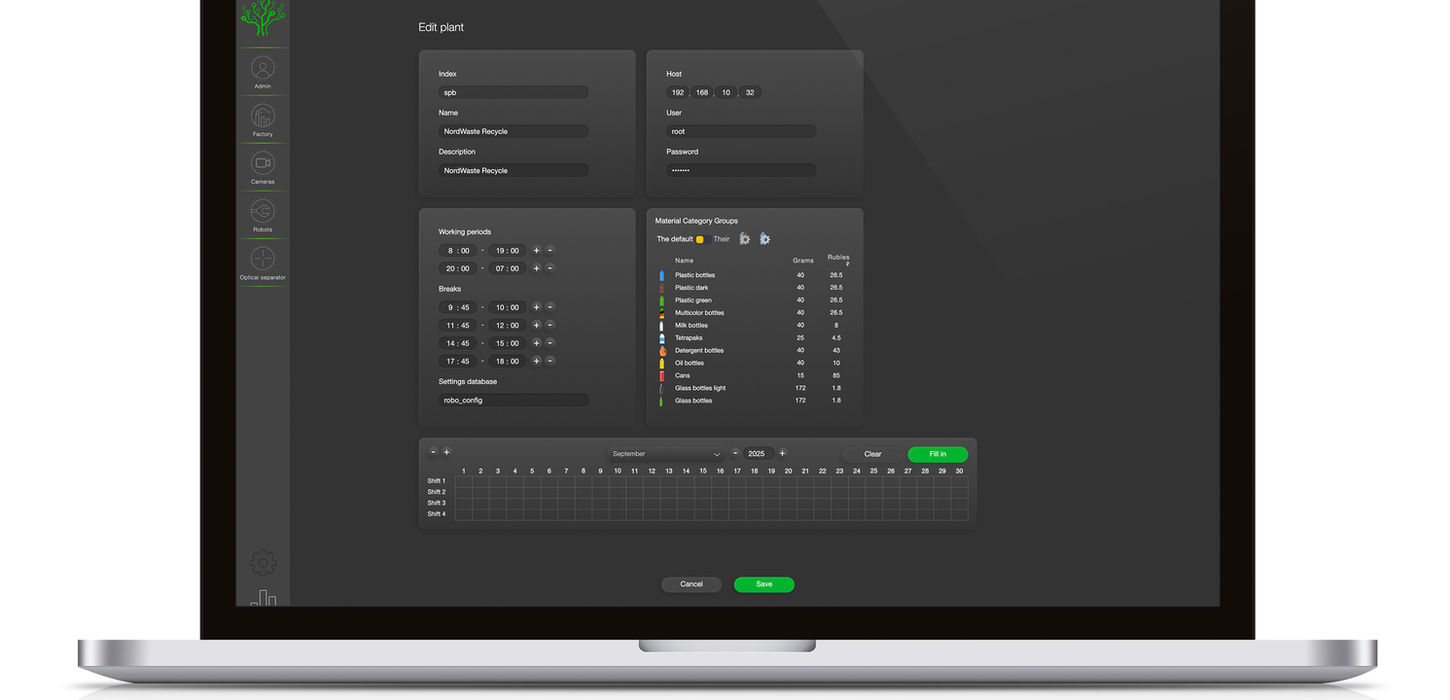

Working and break periods

One of the key advantages of our application is the flexible configuration of work shifts. You can precisely define working hours and break periods, allowing non-working time to be excluded from factory load calculations. This ensures high accuracy in data collection and contributes to more efficient production planning.

Smart shift management

A key advantage of the AI monitoring platform is flexible shift configuration. You can define working hours and break periods precisely, ensuring that non-working time is excluded from system load calculations. This improves data accuracy and supports more efficient production planning.

Compatible products

Seamless monitoring across all InSystem sorters

Smart shift management

A key advantage of the AI monitoring platform is flexible shift configuration. You can define working hours and break periods precisely, ensuring that non-working time is excluded from system load calculations. This improves data accuracy and supports more efficient production planning.

insystem.io monitoring system

test drive

Book a demo

Get a calculation of how our technology

will impact your business metrics

Integrate InSystem products to enhance

your business

How much

money

is wasted?

plastic bottles

oil bottles

milk bottles

detergent bottles

aluminum cans

tetra pak

glass bottles

20+

Types of sorted

materials

24/7 AI Monitoring system

The AI monitoring system ensures secure data processing and full operational visibility. Customisable dashboards let operators track performance, adjust parameters, and analyse results in real time. Continuous model updates improve detection accuracy, keeping sorting lines efficient around the clock.

SKU:0000

>95% detection accuracy

Correct AI classifications

0.01 second per frame

High

calculating time

Ai-feature

sorting

Ai-feature

sorting

100

times

per second

To test and continuously improve our technologies, we’ve established a dedicated monitoring center that analyzes waste streams from a major metropolis with a population of nearly 6 million people. This large-scale, real-world data allows us to train and refine our neural networks, constantly increasing the accuracy and efficiency of our sorting systems.