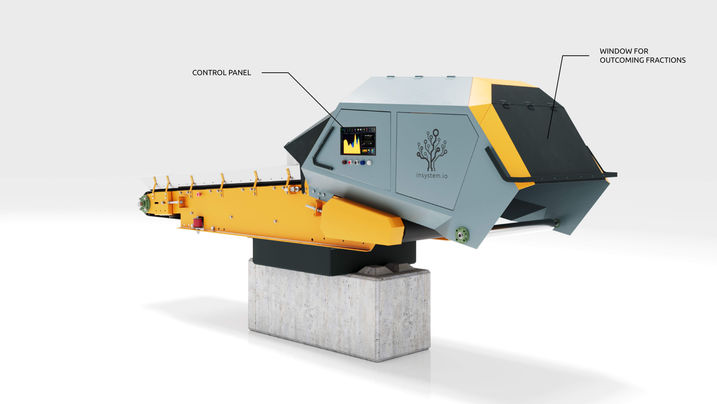

Model InSystem 002

Optical sorter

Up to 20

objects

per second

objects / sec

Up to 22

tons

per hour

The optical sorter increases throughput by automating separation and reducing manual work. It processes up to 22 tons of material per hour with consistent accuracy. The system uses precise air-jet separation based on adjustable sorting parameters and is suitable for recycling, mining, and food industries, adapting easily to different types of materials and production lines.

PURITY LEVELS

Ai + NiR camera

input size up

to 250 mm

Purchase price —

from 85 000 €

Detaled overview

High-speed

vision performance

Our optical sorter uses a high-speed camera with AI analysis that captures up to 100 frames per second, identifying each object in real time.

High resolution and fast exposure ensure accurate recognition of complex materials moving at up to 4 meters per second.

This precision allows the optical sorter to maintain consistent performance even during high-volume operation.

5 SEC RESPOSE TIME

4 METERS /

SEC

FAST EXPOSITION

Cloud statistics

The optical sorter connects to a cloud platform that analyses real-time performance data from every line. Dashboards show sorting efficiency, purity, and throughput, allowing operators to monitor production remotely and detect issues early. AI updates and live statistics keep each sorter running at peak accuracy and uptime.

Real time statistics

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

Dual-direction and flow optimisation

The optical sorter can be configured for upward or downward discharge, adapting to the plant layout and material flow.

Both installation options are available on request, providing flexibility for different optical sorting line designs.

Up and down separation

Up and down separation - depends on the sorting factory design.

Up and down separation - depends on the sorting factory design. Both direction installation is possible on demand. Up and down separation - depends on the sorting factory design. Both direction installation is possible on demand.

Triangular conveyor

The optical sorter uses a triangular conveyor that improves material flow and separation efficiency.

As mixed material moves over the angled section, lighter items lift and slide upward while heavier ones remain on the belt, ensuring steady and precise separation.

separation

FLOW OPTIMIZATION

Conveyor chain

Connecting multiple optical sorters in sequence maintains material flow and consistent throughput.

This configuration supports continuous sorting and helps use space efficiently within the production line.

Design and construction

The optical sorter is built for long operational life in industrial environments. Its modular steel frame allows quick alignment with conveyors or other sorting units, making installation straightforward. The reinforced support structure and high-strength conveyor belt maintain stability and precision under continuous load.

COMPONENT

material

Frame

Steel

Support structure

Steel, concrete

Conveyor belt

High-strength rubber

Technical details

and specifications

The optical sorter includes a self-calibration system that maintains accuracy under changing operating conditions. Its control software enables remote monitoring and fine-tuning to keep performance stable over time. The design supports easy configuration for different material types and process requirements.

BASIC PARAMETRES

Capacity 20 000kg/h

3-15mm nozzle spacing

FRACTIONS

Up to 3 separate fractions

Input fraction size <250 mm

CONVEYOR

High-frequency feedback technology

Conveyor speed 2-4 m/s

Camera

Highly precise 360 analysis

Parameters

Specification

Overall dimensions

4300х1200х1100 mm

Minimum and maximum size of sorted objects

0-250 mm

Power consumption

7,5 kW·h

Operating temperature range

from -20 to +50 °C

Weight

850 kg

Compressed

air requirements

8 bar, 1000 - 3000 L/min

Model InSystem 002

optical separator

up to 20

object

per second

up to 36

tons

per hour

The Optical Sorter - Line utilizes advanced AI technology for automatic material recognition, processing up to 100 frames per second. This high-speed system can handle up to 20 objects per second, sorting up to 36 tons per hour. The sorting is performed using high-pressure jets of compressed air, precisely separating materials based on customizable criteria.

PURITY LEVELS

ai + nir

camera

input size up

to 250 мм

From 85 000 €

up to 20

objects

per second

up to 36

tons

per hour

The optical sorter increases throughput by automating separation and reducing manual work. It processes up to 36 tons of material per hour with consistent accuracy. The system uses precise air-jet separation based on adjustable sorting parameters and is suitable for recycling, mining, and food industries, adapting easily to different types of materials and production lines.

PURITY LEVELS

Ai + NiR camera

input size up to 250 мм

Purchase price

—

from 85 000 €

Model InSystem 002

OPTICAL SORTER

Detaled review

High-speed

vision performance

Our optical sorter uses a high-speed camera with AI analysis that captures up to 100 frames per second, identifying each object in real time.

High resolution and fast exposure ensure accurate recognition of complex materials moving at up to 4 meters per second.

This precision allows the optical sorter to maintain consistent performance even during high-volume operation.

5 SEC RESPOSE TIME

4 METERS /

SEC

FAST EXPOSITION

Cloud statistics

The optical sorter connects to a cloud platform that analyses real-time performance data from every line. Dashboards show sorting efficiency, purity, and throughput, allowing operators to monitor production remotely and detect issues early. AI updates and live statistics keep each sorter running at peak accuracy and uptime.

REALTIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

Up and down separation

The optical sorter can be configured for upward or downward discharge, adapting to the plant layout and material flow.

Both installation options are available on request, providing flexibility for different optical sorting line designs.

Triangular conveyor

The fracture on the conveyor enables efficient separation of light and heavy objects.

As the mixed flow passes over the angled section, lighter objects that were previously compressed within the stream are lifted and slide upward, separating naturally from the heavier ones.

separation

FLOW OPTIMIZATION

Triangular conveyor

The optical sorter uses a triangular conveyor that improves material flow and separation efficiency.

As mixed material moves over the angled section, lighter items lift and slide upward while heavier ones remain on the belt, ensuring steady and precise separation.

separation

FLOW OPTIMIZATION

Ultimate speed camera

The high-speed camera and Ai provides up to 100 frames per second object analisys.

The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

5 SEC RESPOSE TIME

4 METERS /

SEC

FAST EXPOSITION

Statistics

The high-speed camera and Ai provides up to 100 frames per secondobject analisys. The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

REALTIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

Up and down separation

Up and down separation - depends on the sorting factory design.

Both direction installation is possible on demand.

Сombining separators into a line maintains sorting speed, ensures continuous sorting, and saves space in the workroom.

Сombining separators into a line maintains sorting speed, ensures continuous sorting, and saves space in the workroom.

Conveyor chain

Connecting multiple optical sorters in sequence maintains material flow and consistent throughput. This configuration supports continuous sorting and helps use space efficiently within the production line.

Design and construction

This modular design allows for easy integration into existing production lines and can be configured in a series, with each unit sorting specific fractions and passing remaining materials to the next separator. The robust frame and adaptable support structure ensure stability and flexibility in various industrial settings.

CONSTITUENT

MATERIAL

Frame

Steel

Support structure

Steel, stone

Conveyor belt

High-strength rubber

Technical details

and specifications

The optical sorter includes a self-calibration system that maintains accuracy under changing operating conditions. Its control software enables remote monitoring and fine-tuning to keep performance stable over time. The design supports easy configuration for different material types and process requirements.

BASIC PARAMETRES

Capacity

20 000 kg/h

Power consumption 4,5 kW

FRACTIONS

Up to 3

separate fractions

Input fraction size <150 mm

CONVEYOR

High-frequency technology

Conveyor speed

4 - 5 m/s

AUTOMATIC OIL SYSTEM

Highly precise

360 analysis

Parameters

Significance

Overall dimensions

4300х1100х

1100 mm

Minimum and maximum size

of sorted objects

0 - 250 mm

Power consumption

2,5 kW/h

Operating temperature range

from -20

to +50 °C

Weight

850 kg

Compressed

air requirements

8 bar,

2000 L/min

Technical details

and specifications

The Optical Sorter - Line features an advanced self-calibration system for optimal performance under varying conditions. Its proprietary software enables remote monitoring and real-time adjustments, while the modular design allows for easy customization to meet specific industry requirements without complete system replacement.

BASIC PARAMETRES

Capacity

36 000 kg/h

Power consumption

2.5 kW

FRACTIONS

Up to 1

separate fractions

Input fraction size <150 mm

CONVEYOR

High-frequency technology

Conveyor speed

4-5 m/s

CAMERA

Highly precise

360 analysis

Parameters

Significance

Overall dimensions

4300х1100х1100 mm

Minimum and maximum size

of sorted objects

0-250 mm

Power consumption

2,5 kW/h

Operating temperature range

from -20 to +50 °C

Weight

2500 kg

Compressed

air requirements

8 bar, 2000 L/min

Design and construction

The optical sorter is built for long operational life in industrial environments. Its modular steel frame allows quick alignment with conveyors or other sorting units, making installation straightforward. The reinforced support structure and high-strength conveyor belt maintain stability and precision under continuous load.

constituent

material

Frame

Steel

Support structure

Steel, stone

Conveyor belt

High-strength

rubber