Model InSystem 001

Ballistic separator

70 m³

of recycled

waste / hour

objects / sec

3 fractions

sepating option

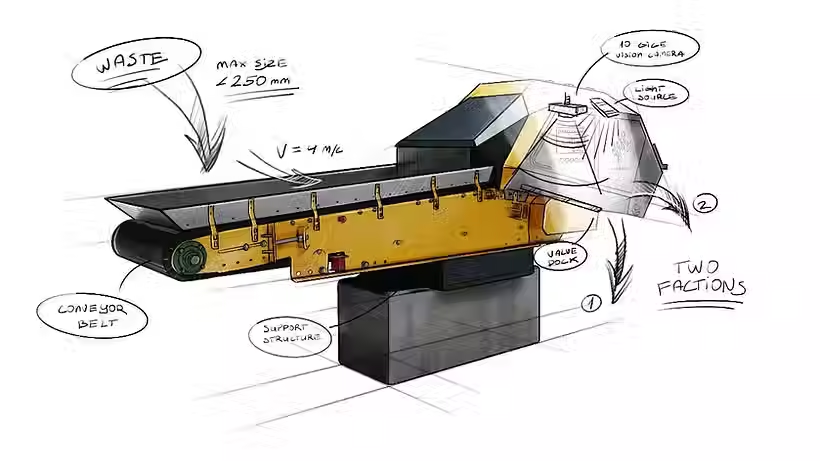

The InSystem ballistic separator improves sorting efficiency by separating mixed waste into clean fine, 2D and 3D fractions. It reduces manual work and stabilises downstream equipment performance. Designed for high throughput, it processes up to 70 cubic metres of waste per hour, ensuring consistent recovery quality across shifts.

hydraulic

lift

automatic

oil system

input size up

to 250 mm

Purchase price —

95 000 €

TOTAL WASTE MASS

Mixed stream after shredding under 500 mm

FINE FRACTIONS

Sand, dust, organics under 20–60 mm

MEDIUM FRACTIONS (2D)

Film, bags, light packaging, cardboard, flakes

HEAVY FRACTIONS (3D)

Stone, chipboard, bricks, metal

Detailed overview

Design and construction

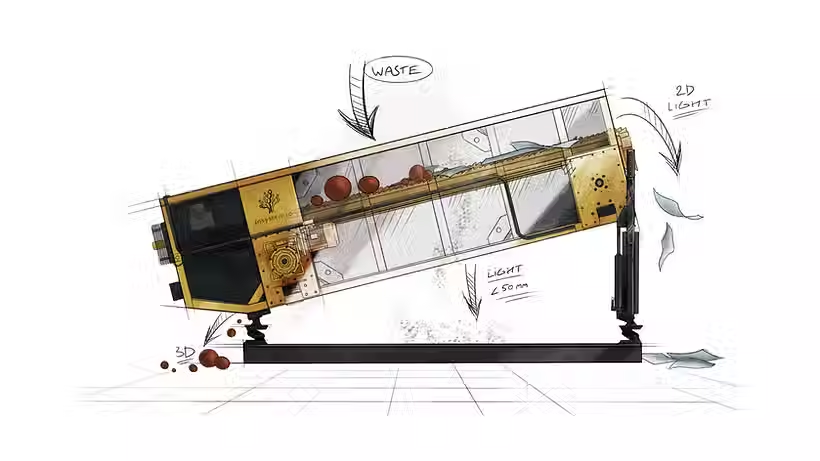

The ballistic separator uses a perforated deck with controlled motion to divide mixed waste by size, shape and density. Fine materials fall through the screen, light 2D items move upward, and heavy 3D objects roll downward by gravity. Adjustable frame angle, fan frequency and screen openings allow fine-tuning for different waste streams and target fraction quality.

Adjustable Parameters

Adjustment Range

Fan Frequency

Frequency converter 0 - 100%

Frame Angle

10 - 30°

Screen Hole Diameter

20, 40 or 60mm

Technical details

and specifications

The InSystem ballistic separator is built for stable performance under changing operating conditions. Its control system supports real-time monitoring and on-site adjustments to maintain consistent separation quality. The modular design makes configuration simple, allowing adaptation to specific plant layouts and material types without full system replacement.

BASIC PARAMETRES

Capacity 70 cubic meters

Power consumption 12,5 kW·h

FRACTIONS

Recognition accuracy >90%

Fine, 2D and 3D fractions

CONVEYOR

Weight of object < 10kg

Larger side size - 40 cm

AUTOMATIC OIL SYSTEM

70 hours of continuous operation

Parameter

Specification

Overall dimensions

4900х2150х1400 mm

Minimum and maximum size of sorted objects

0 - 250 mm

Power consumption

12,5 kW·h

Operating temperature range

from -20 to +50 °C

Weight

2500 kg

Model InSystem 001

Ballistic separator

70 m³

of recycled

waste / hour

3 fractions

sepating option

The Ballistic Separator is a multi-functional machine for handling different types of waste. At the inlet, the device accepts a mixed waste stream including paper, light packaging, construction waste and municipal solid waste.

hydraulic

lift

automatic

oil system

input size up

to 250 мм

175 000 €

70 m³

of recycled

waste / hour

3 fractions

sepating option

The InSystem ballistic separator improves sorting efficiency by separating mixed waste into clean fine, 2D and 3D fractions. It reduces manual work and stabilises downstream equipment performance. Designed for high throughput, it processes up to 70 cubic metres of waste per hour, ensuring consistent recovery quality across shifts.

hydraulic

lift

automatic

oil system

input size up to 250 мм

Purchase price

—

95 000 €

Model InSystem 001

BALLISTIC SEPARATOR

TOTAL WASTE MASS

Mixed stream after shredding under 500 mm

FINE FRACTIONS

Sand, dust, organics

under 20 - 60 mm

MEDIUM FRACTIONS (2D)

Plastic bags, packaging,

cardboards, flakes

HEAVY FRACTIONS (3D)

Stone, chipboard, bricks, metal

Design and construction

The ballistic separator uses a perforated deck with controlled motion to divide mixed waste by size, shape and density. Fine materials fall through the screen, light 2D items move upward, and heavy 3D objects roll downward by gravity. Adjustable frame angle, fan frequency and screen openings allow fine-tuning for different waste streams and target fraction quality.

Adjustable Parameters

Adjustment Range

Fan Frequency

0 - 50 Khz

Frame Angle

10 - 30°

Screen Hole Diameter

20, 40, 60 mm

Design and construction

The debris flows through the loading chamber to the perforated sieve. Special jagged slides move the 3D debris upwards. The heavy 3D fraction rolls downwards under the force of gravity. The smallest fraction is spilled through the sieve. This separation allows for efficient sorting and processing of different types of waste, optimising the recycling process.

Adjustable Parameters

Adjustment Range

Fan Frequency

0-50 Khz

Frame Angle

10-30°

Screen Hole Diameter

20, 40, 60mm

Technical details

and specifications

The InSystem ballistic separator is built for stable performance under changing operating conditions. Its control system supports real-time monitoring and on-site adjustments to maintain consistent separation quality. The modular design makes configuration simple, allowing adaptation to specific plant layouts and material types without full system replacement.

BASIC PARAMETRES

Capacity

70 cubic meters

Power consumption

7 kW

FRACTIONS

Recognition accuracy >90%

2D and 3D fractions

CONVEYOR

Weight of object

< 10kg

Larger side size -

40 cm

AUTOMATIC OIL SYSTEM

70 hours of continuous operation

Adjustable Parameters

Adjustment Range

Overall dimensions

4900х2150х

1400 mm

Minimum and maximum size of sorted objects

0 - 300 mm

Power consumption

2,5 kW/h

Operating temperature range

from -20

to +50 °C

Weight

2500 kg

Technical details

and specifications

The Ballistic Sorter - Line features an advanced self-calibration system for optimal performance under varying conditions. Its proprietary software enables remote monitoring and real-time adjustments, while the modular design allows for easy customization to meet specific industry requirements without complete system replacement.

BASIC PARAMETRES

Capacity

15 000 kg/h

Power consumption

7 kW

FRACTIONS

Recognition accuracy >90%

2D and 3D fractions

CONVEYOR

Weight of object

< 10kg

Larger side size -

40 cm

AUTOMATIC OIL SYSTEM

70 hours of continuous operation

Parameters

Significance

Overall dimensions

4900х2150х1400 mm

Minimum and maximum size of sorted objects

0 - 300 mm

Power consumption

2,5 kW/h

Operating temperature range

from -20 to +50 °C

Weight

2500 kg

Place in sorting line