Model InSystem 002

optical separator

up to 20

object

per second

up to 36

tons

per hour

The Optical Sorter - Line utilizes advanced AI technology for automatic material recognition, processing up to 100 frames per second. This high-speed system can handle up to 20 objects per second, sorting up to 36 tons per hour. The sorting is performed using high-pressure jets of compressed air, precisely separating materials based on customizable criteria.

PURITY LEVELS

ai + nir

camera

input size up

to 250 мм

From 85 000 €

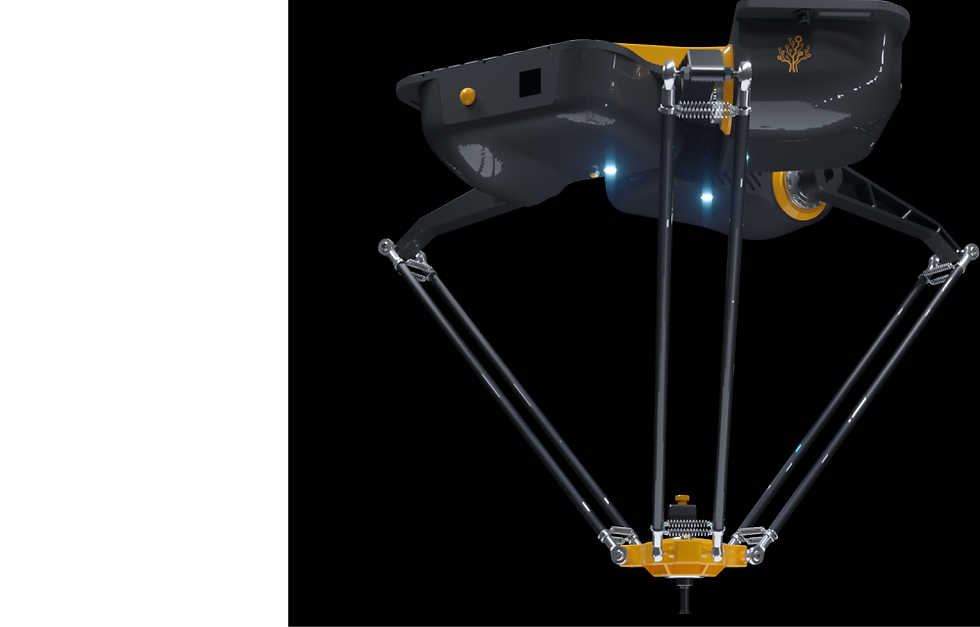

2nd Generation

Recycling robots

Robotic waste sorting system

1 object / second

objects / sec

24/7

365 days / year

Recycling robots lower sorting costs by automating manual picks while increasing purity and recovery. This high-speed system can handle up

to 60 objects per minute. The 2nd generation of recycling robots can be installed in 1 day.

lifts up

to 1 kg

Ai + NiR camera

(optional)

input size up

to 250 mm

Purchase price —

45 000 €

85 000 €

Rent for test –

You can always fire him!

The minimum probation period is 6 months.

20+

Types of sorted

materials

plastic bottles

oil bottles

milk bottles

detergent bottles

tin cans

tetrapacks

glass bottles

wood chips

chipboard

mixed stone

iron ore

-

Dull-dirty-dangerous work

-

Salary and social contribution taxes

-

Seasonal work

-

Lack of control

-

Low effectiveness, need to be educated

-

Thievery

Less labour. More automation.

More sorting

Less waste

-

Active 24/7

-

Remote monitoring

-

Algorithm optimization

-

Cost effectiveness

-

Low lease costs

-

No fraud

Less labour. More automation.

More sorting -

Less waste

One day installation

Deploy InSystem recycling robots at your sorting plant as an independent system or alongside people.

The plant layout stays the same.

Installation

in 1 day

Deploy InSystem recycling robots at your sorting plant as an independent system or alongside people. The plant layout stays the same.

Detailed overview

Special offers

Automatically updating algorithm

Updated image processing algorithm

Data

on sorting results

24/7

Monitoring system

1. Information from the cameras is sent to a unified control centre for remote monitoring and service.

2. The sorting algorithms are optimised automatically as neural networks are trained and the volume of sorted waste increases.

Updated image processing algorithm

Data

on sorting

results

24/7

Monitoring system

1. Information from the cameras is sent to a unified control centre for remote monitoring and service.

2. The sorting algorithms are optimised automatically as neural networks are trained and the volume of sorted waste increases.

Cloud statistics

The cloud platform delivers complete visibility into your recycling operation across all shifts. Advanced analytics, real-time alerts and interactive dashboards give you clear insights into composition tracking. Designed for multi-plant scale and easy integration,

the platform supports faster decisions, tighter control and improved recovery outcomes.

REAL TIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

Timeline

2017

Company incorporation.

First concept designs

2018

In-house technology development.

The 1st generation prototypes

of AI recycling robots

2020

Implementation of 6 robots at the plant.

Start of automated operation

2021

Scaling.

Robotic sorting installation

across 5 factories in different cities

2022

Launch of the monitoring system at factories.

Data collection and analysis of waste generated

by 6 million people

2023

Recycling robots upgrade.

Development of concepts and designs

for the 2nd generation of recycling robots

2024

Company incorporation

in the Netherlands

2025

Recycling robots release in November

Ai-feature

sorting

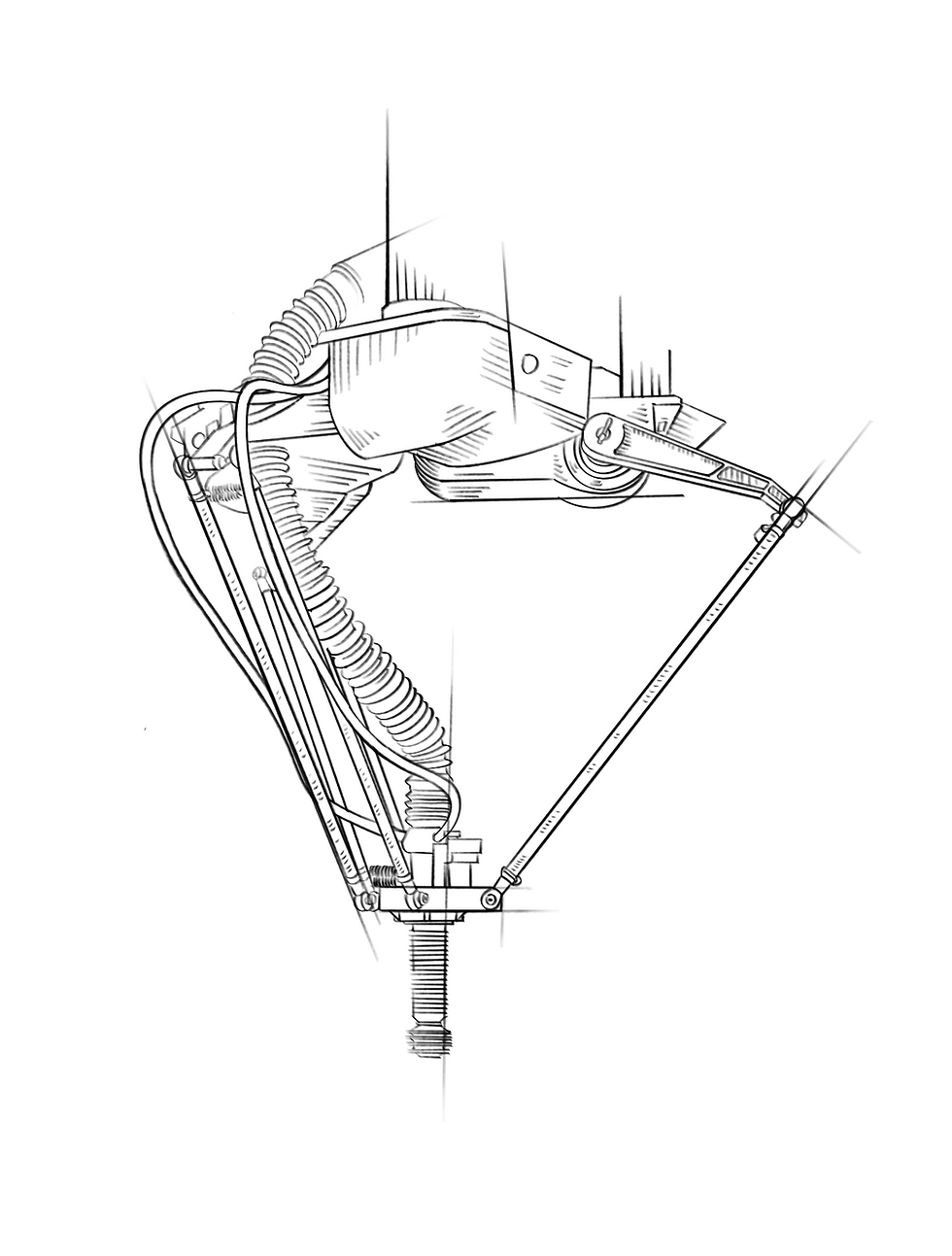

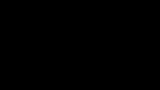

What's the difference between 1st and 2nd generation?

We kept the best features from the first generation and built more efficient version.

The new generation of recycling robots are easier to install, faster in operation and more cost-effective to integrate into your sorting line.

1st

generation

2nd

generation

Price

135 000 euro

85 000 euro 45 000 euro

CONSTRUCTION

Requires manual inspection after impacts

High impact resistance

INSTALLATION

10-15 days

1 day

maintenance

Requires manual service

Self-cleaning

processing speed

1 object / sec

1 object / sec

plastic bottles

oil bottles

milk bottles

detergent bottles

tin cans

tetrapacks

glass bottles

20+

Types of sorted

materials

1 object / sec

24/7

365 days/

year

Recycling robots lower sorting costs by automating manual picks while increasing purity and recovery. This high-speed system can handle up to 60 objects per minute. The 2nd generation of recycling robots can be installed in 1 day.

lifts up

to 1 kg

Ai + NiR camera

input size up to 250 мм

Purchase price

—

45 000 €

85 000 €

Rent for test –

You can always fire him!

The minimum probation period

is 6 months

2nd Generation

RECYCLING Robots

Robotic waste sorting system

2024

Company incorporation

in the Netherlands

2023

Recycling robots upgrade.

Development of concepts and designs

for the 2nd generation of recycling robots

2022

Launch of the monitoring system

at factories.

Data collection and analysis

of waste generated by 6 million people

2021

Scaling.

Robotic sorting installation

across 5 factories in different cities

2020

Implementation of 6 robots at the plant.

Start of automated operation

2018

In-house technology development.

The 1st generation prototypes

of AI recycling robots

2017

Company incorporation.

First concept designs

Detaled review

Timeline

What's the difference between 1st

and 2nd generation?

We kept the best features from the first generation and built more efficient version.

The new generation of recycling robots are easier to install, faster in operation and more cost-effective to integrate into your sorting line.

Сloud statistics

The cloud platform delivers complete visibility into your recycling operation across all shifts. Advanced analytics, real-time alerts and interactive dashboards give you clear insights into composition tracking. Designed for multi-plant scale and easy integration, the platform supports faster decisions, tighter control and improved recovery outcomes.

REALTIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

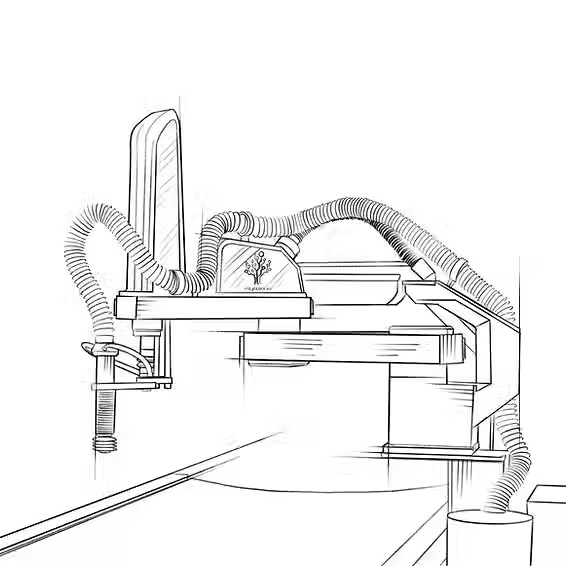

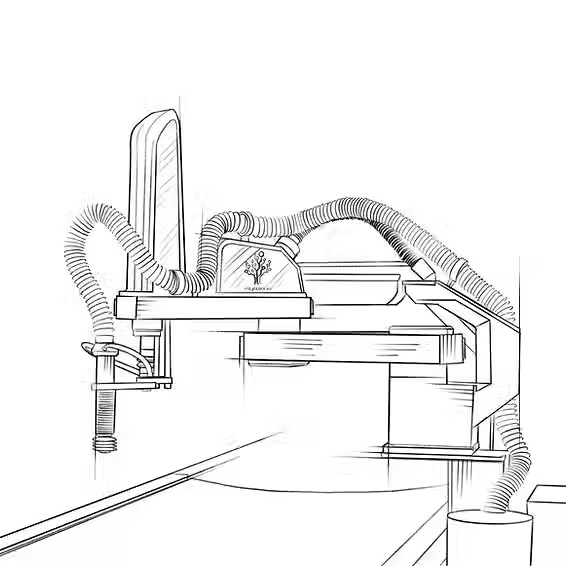

Triangular conveyor

The fracture on the conveyor enables efficient separation of light and heavy objects.

As the mixed flow passes over the angled section, lighter objects that were previously compressed within the stream are lifted and slide upward, separating naturally from the heavier ones.

separation

FLOW OPTIMIZATION

Ultimate speed camera

The high-speed camera and Ai provides up to 100 frames per second object analisys.

The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

5 SEC RESPOSE TIME

4 METERS /

SEC

FAST EXPOSITION

Statistics

The high-speed camera and Ai provides up to 100 frames per secondobject analisys. The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

REALTIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

Up and down separation

Up and down separation - depends on the sorting factory design.

Both direction installation is possible on demand.

Сombining separators into a line maintains sorting speed, ensures continuous sorting, and saves space in the workroom.

Сombining separators into a line maintains sorting speed, ensures continuous sorting, and saves space in the workroom.

Design and construction

This modular design allows for easy integration into existing production lines and can be configured in a series, with each unit sorting specific fractions and passing remaining materials to the next separator. The robust frame and adaptable support structure ensure stability and flexibility in various industrial settings.

CONSTITUENT

MATERIAL

Frame

Steel

Support structure

Steel, stone

Conveyor belt

High-strength rubber

Design and construction

The modular design of InSystem recycling robots enables smooth integration with various conveyor lines and waste streams. Built for industrial durability, each recycling robot combines a steel and aluminium structure with high-strength components for stable, long-term operation. Designed for easy maintenance, the robots deliver reliable performance and scalability for evolving recycling needs.

Component

material

Frame

Steel

Support structure

Steel, aluminium

Conveyor belt

High-strength rubber

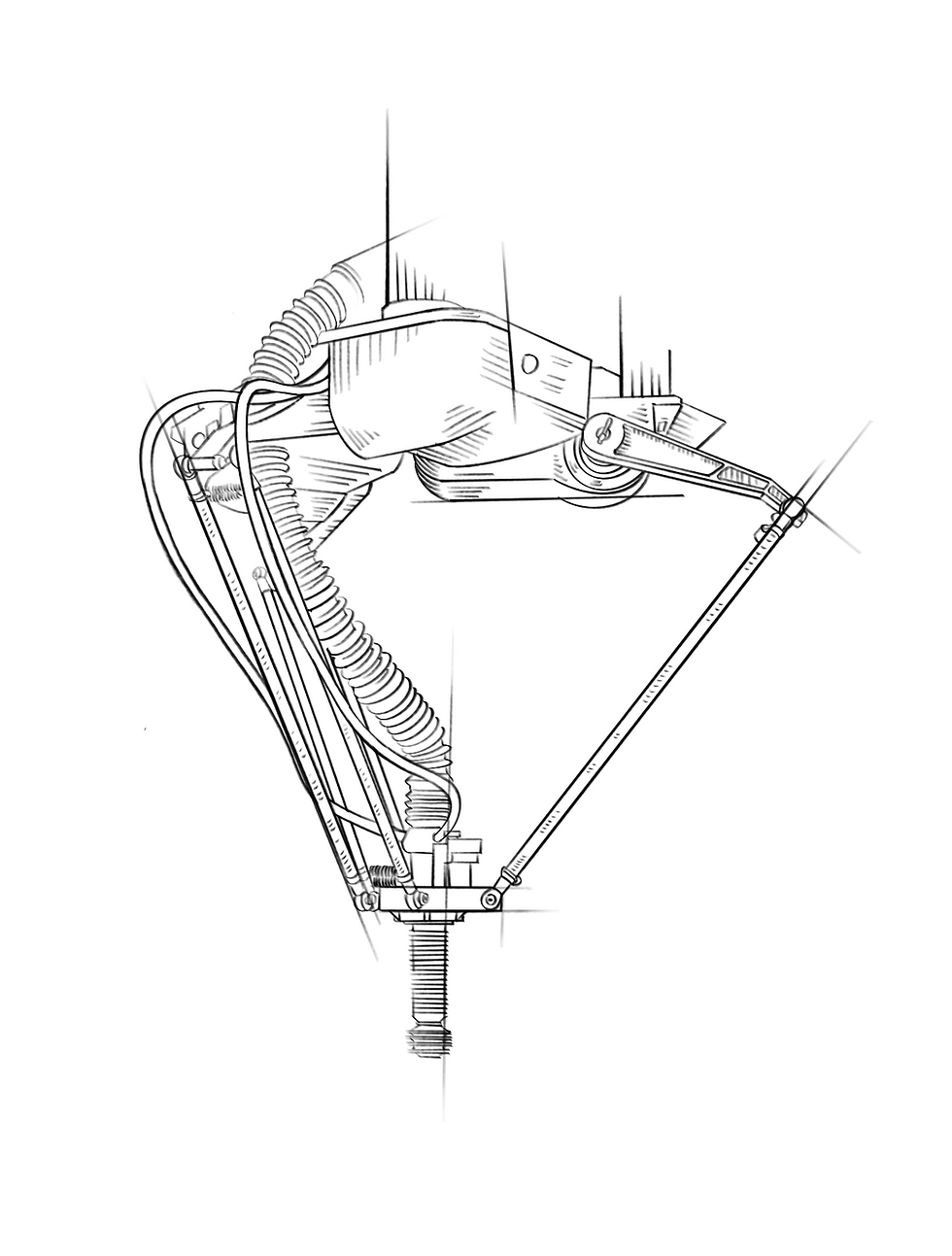

Technical details

and specifications

The InSystem Recycling Robot (SCU: 0105) is a high-performance unit for automated waste sorting. Equipped with industrial-grade cameras, spectral sensors, and advanced AI recognition, it identifies material, shape and colour with up to 99% accuracy. Each frame is processed in just 0.01 seconds, allowing the robot to sort up to 3,600 items per hour with over 95% recycling efficiency.

BASIC PARAMETRES

Power consumption 2.5 kW

Capacity 1700 - 3600 picks / h

FRACTIONS

Up to 12

separate fractions

Input fraction size <150 mm

CONVEYOR

High-frequency technology

Conveyor speed

0.2 - 1 m / s

CAMERA

High-precision analysis at 200 frames per second

Parameters

Significance

Overall dimensions

850х820х800 mm

Minimum and maximum size

of sorted objects

0-250 mm

Power consumption

2,5 kW/h

Operating temperature range

from -10

to +50 °C

Weight

48 kg

Compressed

air requirements

8 bar,

200 L/min

Technical details

and specifications

The Optical Sorter - Line features an advanced self-calibration system for optimal performance under varying conditions. Its proprietary software enables remote monitoring and real-time adjustments, while the modular design allows for easy customization to meet specific industry requirements without complete system replacement.

BASIC PARAMETRES

Capacity

36 000 kg/h

Power consumption

2.5 kW

FRACTIONS

Up to 1

separate fractions

Input fraction size <150 mm

CONVEYOR

High-frequency technology

Conveyor speed

4-5 m/s

CAMERA

Highly precise

360 analysis

Parameters

Significance

Overall dimensions

4300х1100х1100 mm

Minimum and maximum size

of sorted objects

0-250 mm

Power consumption

2,5 kW/h

Operating temperature range

from -20 to +50 °C

Weight

2500 kg

Compressed

air requirements

8 bar, 2000 L/min

Technical details

and specifications

The InSystem Recycling Robot (SCU: 0105) is a high-performance unit for automated waste sorting. Equipped with industrial-grade cameras, spectral sensors, and advanced AI recognition, it identifies material, shape and colour with up to 99% accuracy. Each frame is processed in just 0.01 seconds, allowing the robot to sort up to 3,600 items per hour with over 95% recycling efficiency.

BASIC PARAMETRES

Power consumption 2.5 kW

Capacity 1700 - 3600 picks / h

FRACTIONS

Up to 12 separate fractions

Input fraction size <150 mm

CONVEYOR

High-frequency technology

Conveyor speed 0.2 -1 m / s

Camera

High-precision analysis at 200 frames per second

PARAMETER

Specification

Overall dimensions

850х820х800 mm

Minimum and maximum size of sorted objects

0-250 mm

Power consumption

2,5 kW/h

Operating temperature range

from -10 to +50 °C

Weight

48 kg

Compressed

air requirements

8 bar, 200 L/min

user-friendly interface

reliability and ease

of maintenance

cloud access

quick installation

in 1 day

user-friendly interface

reliability and ease of maintenance

cloud access

quick installation

in 1 day

Service

The InSystem team provides responsive technical support to keep your recycling robots operating without interruption. Our specialists deliver quick diagnostics and professional solutions to any technical issue, helping minimise downtime and maintain consistent performance. We are always available for remote assistance, consultations and on-site configuration when needed.

The InSystem team provides responsive technical support to keep your recycling robots operating without interruption. Our specialists deliver quick diagnostics and professional solutions to any technical issue, helping minimise downtime and maintain consistent performance. We are always available for remote assistance, consultations and on-site configuration when needed.

RECYCLING Robots

Learn more about recycling robots

Learn

more about recycling robots

Book a demo

Receive a tailored assessment showing how our technology can improve your key performance metrics

Integrate InSystem recycling robots to enhance your business

Book a demo

Receive a tailored assessment showing

how our technology can improve your

key performance metrics

Integrate InSystem recycling robots

to enhance your business

Design and construction

The modular design of InSystem recycling robots enables smooth integration with various conveyor lines and waste streams. Built for industrial durability, each recycling robot combines a steel and aluminium structure with high-strength components for stable, long-term operation. Designed for easy maintenance, the robots deliver reliable performance and scalability for evolving recycling needs.

Component

material

Frame

Steel

Support structure

Steel, stone

Conveyor belt

High-strength

rubber