Advanced potato

sorting machines

Boost quality & yield

Ai-feature

sorting

FULL CONTROL

FOR MAXIMUM PRODUCT VALUE

Using hyperspectral imaging and deep learning, our potato sorting systems deliver up to 98.7% accuracy across high-throughput lines. They identify and separate potatoes by defect, color, size, or shape. The system automatically adapts to different varieties and surface conditions, keeping performance consistent

across all batches.

6+

defect

categories

Precise sorting by defect and size

growth cracks

misshapen

stones and clods

rhizoctonia

damage

aging

Ai-feature

sorting

Improving food quality and safety

Growing demand for visually perfect and safe food products is reshaping modern potato processing. To meet higher standards, producers are turning to potato sorting machines that combine speed, accuracy, and consistency. Our machines use computer vision, AI, and hyperspectral imaging to analyse each potato in detail. Unlock detection of surface defects, contamination, and maturity levels with precision that goes far beyond manual inspection.

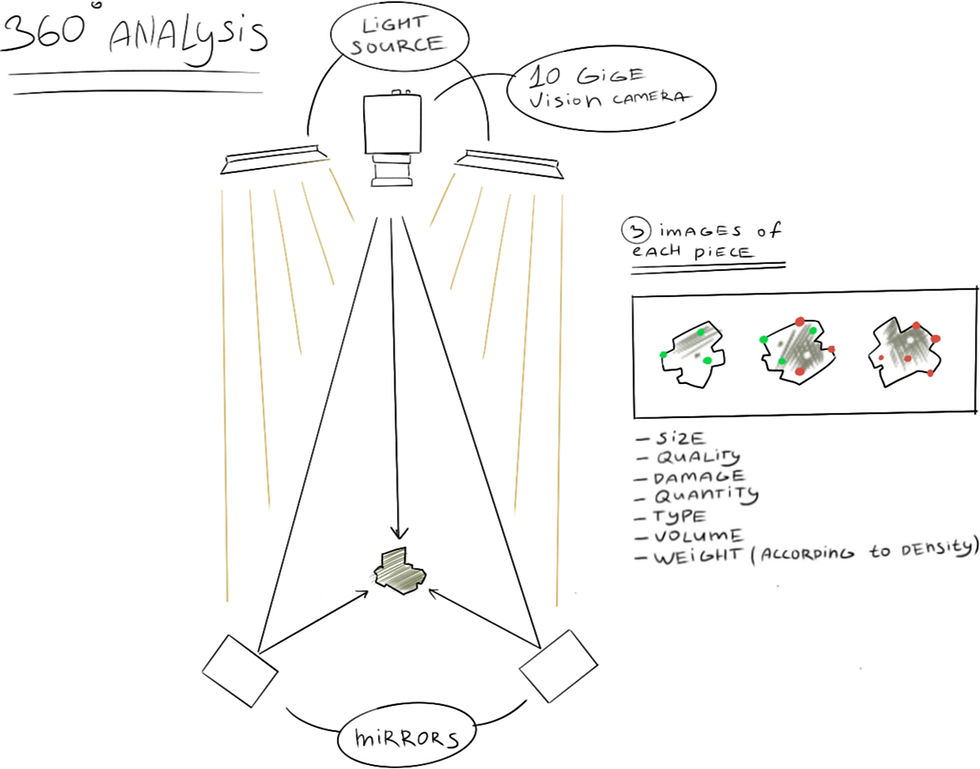

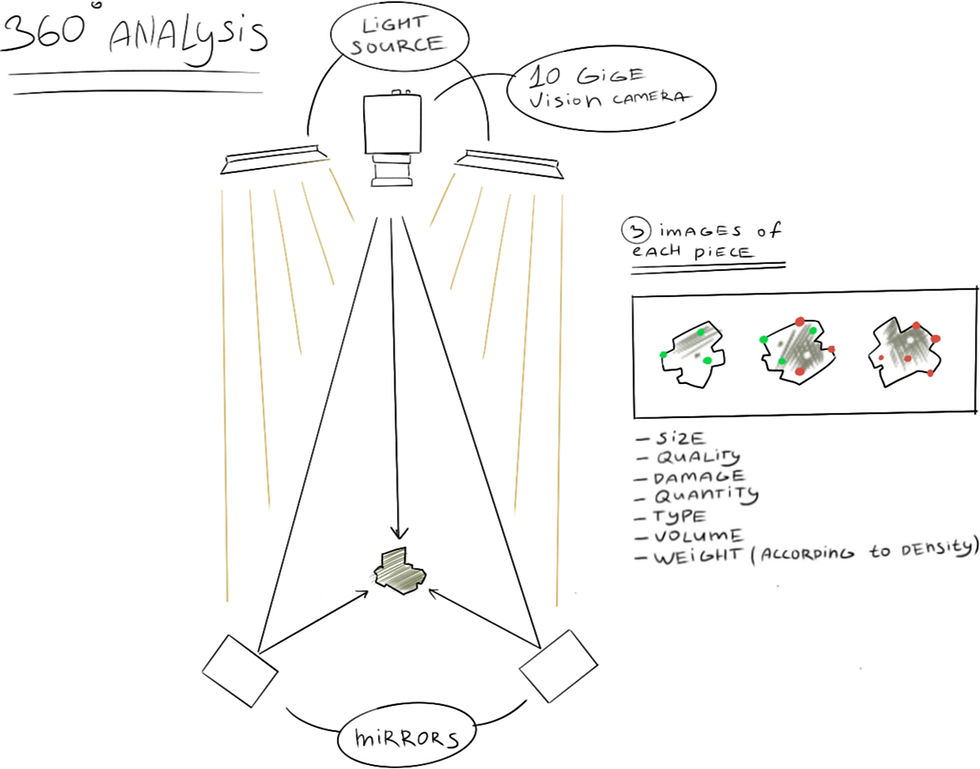

360° camera

The high-speed camera with a dual-mirror system captures a full 360-degree view of each potato as it passes through the potato sorting machine. By recording all sides simultaneously, it detects even the smallest surface defects or shape irregularities. This detailed imaging delivers reliable data for quality control, helping optimise performance across the entire sorting process.

Up and down separation

Up and down separation - depends on the sorting factory design.

Up and down separation - depends on the sorting factory design. Both direction installation is possible on demand. Up and down separation - depends on the sorting factory design. Both direction installation is possible on demand.

Key

benefits

Higher Yield

Reduce waste and maximise output through precise defect detection.

Improved Quality Control

Remove damaged or contaminated potatoes to ensure product consistency.

Size & Weight Grading

Calibrate sorting for retail, processing, and seed potato lines.

Labor Savings

Cut manual work with reliable, automated potato sorting.

EU-Compliant & Sustainable

Use energy-efficient, hygienic systems that meet EU standards.

Explore InSystem

potato sorting equipment

FULL CONTROL

For maximum product value

Using hyperspectral imaging and deep learning, our potato sorting systems deliver up to 98.7% accuracy across high-throughput lines. They identify and separate potatoes by defect, color, size, or shape. The system automatically adapts to different varieties and surface conditions, keeping performance consistent across all batches.

6+

Defect categories

Precise sorting by defect

and size

growth cracks

misshapen

stones and clods

rhizoctonia

damage

aging

Improving food quality and safety

Growing demand for visually perfect and safe food products is reshaping modern potato processing. To meet higher standards, producers are turning to potato sorting machines that combine speed, accuracy, and consistency. Our machines use computer vision, AI, and hyperspectral imaging to analyse each potato in detail. Unlock detection of surface defects, contamination, and maturity levels with precision that goes far beyond manual inspection.

Improving & safeguarding food production

Stricter food safety regulations and growing consumer demand for visually perfect, high-quality products are driving the need for advanced sorting technologies. Innovations such as machine vision, AI, and hyperspectral imaging are significantly enhancing sorting precision by detecting subtle defects, contaminants, and optimal ripeness.

360° camera

The high-speed camera with a dual-mirror system captures a full 360-degree view of each potato as it passes through the potato sorting machine. By recording all sides simultaneously, it detects even the smallest surface defects or shape irregularities. This detailed imaging delivers reliable data for quality control, helping optimise performance across the entire sorting process.

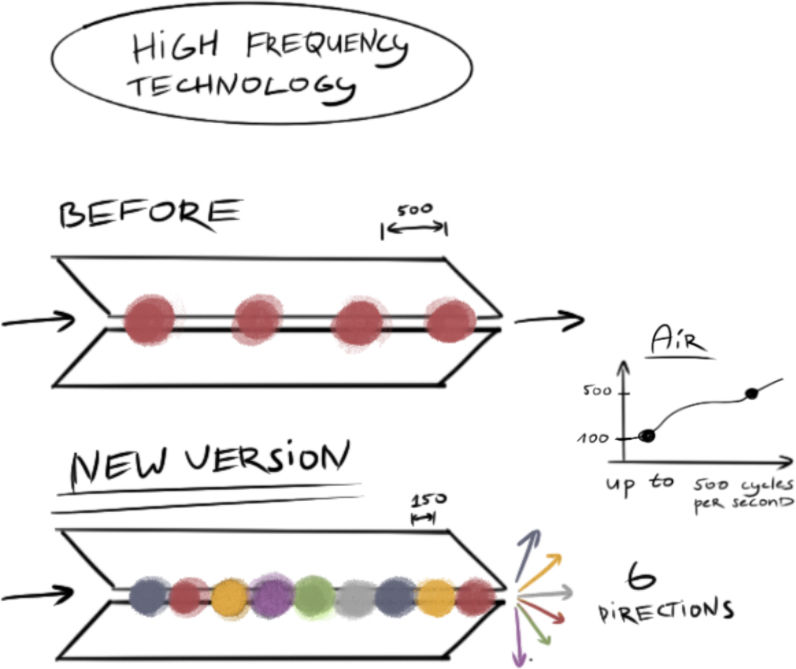

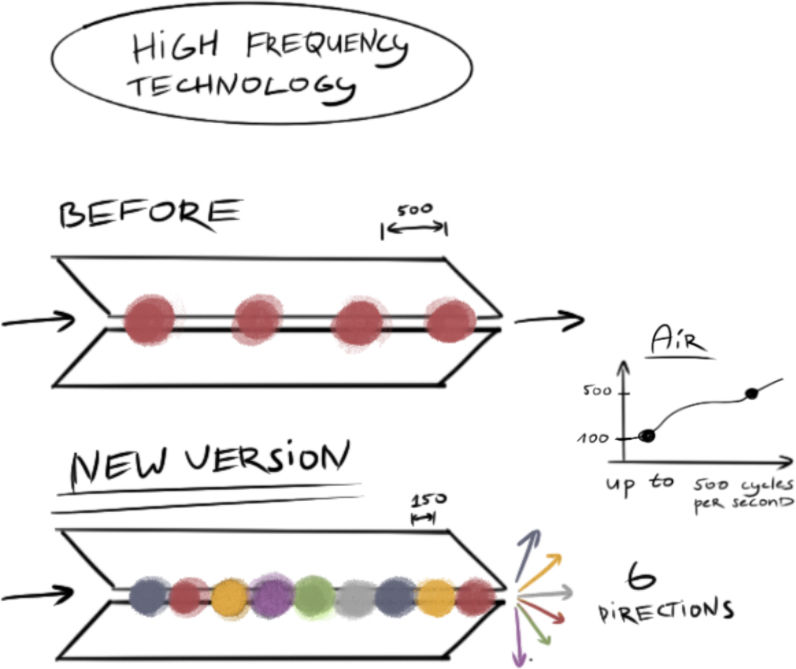

Dual-direction and flow optimisation

Separation direction can be configured for upward or downward discharge, depending on the plant layout and material flow.

Both installation orientations are available on request to ensure flexibility in sorting system design.

Higher Yield

Reduce waste and maximise output through precise defect detection.

Improved Quality Control

Remove damaged or contaminated potatoes to ensure product consistency.

Size & Weight Grading

Calibrate sorting for retail, processing, and seed potato lines.

Labor Savings

Cut manual work with reliable, automated potato sorting.

EU-Compliant & Sustainable

Use energy-efficient, hygienic systems that meet EU standards.

Types of ore sorting on our equipment

.png)

Setting category criteria

The sorter compares objects to user-defined accept/reject criteria to identify and remove defective products and foreign material (FM) from the production line, or to separate product of different grades or types of materials.

.png)

Recognizing pieces with the camera

Depending on the types of sensors used and the software-driven intelligence of the image processing system, optical sorters can recognize an object's characteristics:

color

size

shape

strucaral properties

chemical composition

.png)

Sorting into 2+ segments

Compared to manual sorting, which is subjective and incon-sistent, optical sorting helps improve product quality, maximize throughput and increase yields while reducing labor costs.

2 type

ballistic separation

.png)

Uploading material to tape

Loading material onto the belt.

.png)

Separation with grids

Materials are categorized accor-ding to their size. The overall flow flies through several stages, each characterized by the size of the hole in the mesh into which the material can fall.

.png)

Sorting into 2 or 6 segments

Compared to manual sorting, which is subjective and incon-sistent, optical sorting helps improve product quality, maximize throughput and increase yields while reducing labor costs.

microsort

SCU: 0802

.png)

Setting category criteria

The sorter compares objects to user-defined accept/reject criteria to identify and remove defective products and foreign material (FM) from the production line, or to separate product of different grades or types of materials.

.png)

Recognizing pieces with the camera

Depending on the types of sensors used and the software-driven intelligence of the image processing system, optical sorters can recognize an object's characteristics:

color

size

shape

strucaral properties

chemical composition

.png)

Sorting into 2+ segments

Compared to manual sorting, which is subjective and inconsistent, optical sorting helps improve product quality, maximize throughput and increase yields while reducing labor costs.

.jpg)

2 type

Ballistic separation

MicroSort

SCU: 0802

.png)

Uploading material to tape

Loading material onto the belt.

.png)

Separation with grids

Materials are categorized according to their size. The overall flow flies through several stages, each characterized by the size of the hole in the mesh into which the material can fall.

.png)

Sorting into 2 or 6 segments

Compared to manual sorting, which is subjective and inconsistent, optical sorting helps improve product quality, maximize throughput and increase yields while reducing labor costs.

.png)

.png)

.png)